What is a Thermometer Sensor and How Does It Work in Different Applications

A thermometer sensor is an essential device used for measuring temperature in various contexts, ranging from scientific research to everyday household applications. These sensors harness the principles of thermodynamics to provide accurate and reliable readings, making them invaluable tools in sectors such as healthcare, industrial processes, and environmental monitoring. Understanding how thermometer sensors operate and their diverse applications can deepen our appreciation for their role in contemporary technology.

In different settings, thermometer sensors can take on various forms and operate using distinct methodologies. For instance, thermocouples, resistance temperature detectors (RTDs), and infrared sensors each utilize unique mechanisms to detect temperature changes. These variations allow for tailored applications, whether in precision laboratory settings, HVAC systems, or even in food safety monitoring. Awareness of how these devices function and the range of environments in which they can be effectively employed highlights their significance in maintaining safety and efficiency across multiple fields.

What is a Thermometer Sensor?

A thermometer sensor is a device that measures temperature, converting it into an electrical signal that can be read and analyzed. These sensors can employ various methods to detect temperature changes, such as thermocouples, resistance temperature detectors (RTDs), and thermistors. Each type operates on different principles: thermocouples generate a voltage based on the temperature difference between two junctions, while RTDs and thermistors change their resistance according to temperature variations. This versatility allows thermometer sensors to be utilized in numerous applications across various industries.

In industrial settings, thermometer sensors play a crucial role in processes that require precise temperature control, such as chemical manufacturing and food processing. By continuously monitoring temperatures, these sensors help maintain optimal conditions, ensuring product quality and safety. In the medical field, thermometer sensors are vital for monitoring patient temperatures, enabling timely diagnosis and treatment. Additionally, these sensors are also commonly used in domestic environments, such as in household appliances and HVAC systems, contributing to energy efficiency and comfort. The diverse applications of thermometer sensors highlight their importance in modern technology and daily life.

What is a Thermometer Sensor and How Does It Work in Different Applications

| Sensor Type | Temperature Range | Accuracy | Response Time | Common Applications |

|---|---|---|---|---|

| Thermocouple | -200°C to +1250°C | ±1°C | Fast (millisecond range) | Industrial applications, Furnace monitoring |

| RTD (Resistance Temperature Detector) | -200°C to +850°C | ±0.1°C | Moderate (seconds range) | Laboratories, HVAC systems |

| Thermistor | -50°C to +150°C | ±0.5°C | Fast (milliseconds) | Medical devices, Consumer electronics |

| Infrared Sensor | -50°C to +500°C | ±1°C | Very Fast (microsecond range) | Non-contact temperature measurement, Building inspection |

| Bimetallic Strip | -50°C to +150°C | ±2°C | Slow (seconds) | Household thermometer, Industrial heating systems |

Understanding the Basic Principles of Temperature Measurement

A thermometer sensor is a crucial instrument used to measure temperature across various environments and applications. At its core, temperature measurement relies on the principles of thermal expansion, resistance changes, or voltage variations in different materials. The most common types of thermometer sensors include thermocouples, thermistors, and infrared sensors, each operating based on specific physical properties that correlate to temperature.

In practical applications, understanding the basic principles of temperature measurement is essential for accuracy and reliability. For instance, in industrial settings, thermocouples utilize the Seebeck effect, where two dissimilar metals generate a voltage proportional to the temperature difference between their junctions. This principle allows for precise temperature readings critical in processes like metal forging or chemical reactions. On the other hand, thermistors are often employed in consumer electronics, where their resistance significantly changes with temperature, resulting in highly sensitive measurements for devices such as thermostats.

Infrared sensors demonstrate yet another principle by measuring the infrared radiation emitted by objects, allowing for non-contact temperature measurements. This capability is particularly advantageous in applications where the target is moving or inaccessible, such as monitoring temperatures in hazardous environments. By leveraging these different principles of temperature measurement, thermometer sensors are integral in enhancing safety, efficiency, and performance across various fields, including healthcare, automotive, and environmental monitoring.

Types of Thermometer Sensors and Their Unique Features

Thermometer sensors come in various types, each designed to address specific needs across diverse applications. The most common types include digital thermometers, thermocouples, resistance temperature detectors (RTDs), and infrared sensors.

Digital thermometers use electronic sensors to provide quick and accurate temperature readings, making them ideal for medical and food safety applications. Thermocouples, on the other hand, are widely used in industrial settings due to their ability to measure a wide temperature range and respond rapidly to temperature changes.

RTDs are known for their precision and stability, making them suitable for laboratory and scientific applications where exact measurements are critical. Infrared sensors offer a non-contact method of measuring temperature, which is beneficial in scenarios where the object being measured is moving or difficult to access, such as in HVAC systems or electrical equipment monitoring.

Tips: When selecting a thermometer sensor for your application, consider the temperature range, response time, and environmental conditions. For instance, if you require rapid measurements, a thermocouple might be the best choice. Always ensure the sensor type you choose is compatible with your measurement environment to obtain accurate and reliable data.

Applications of Thermometer Sensors in Various Industries

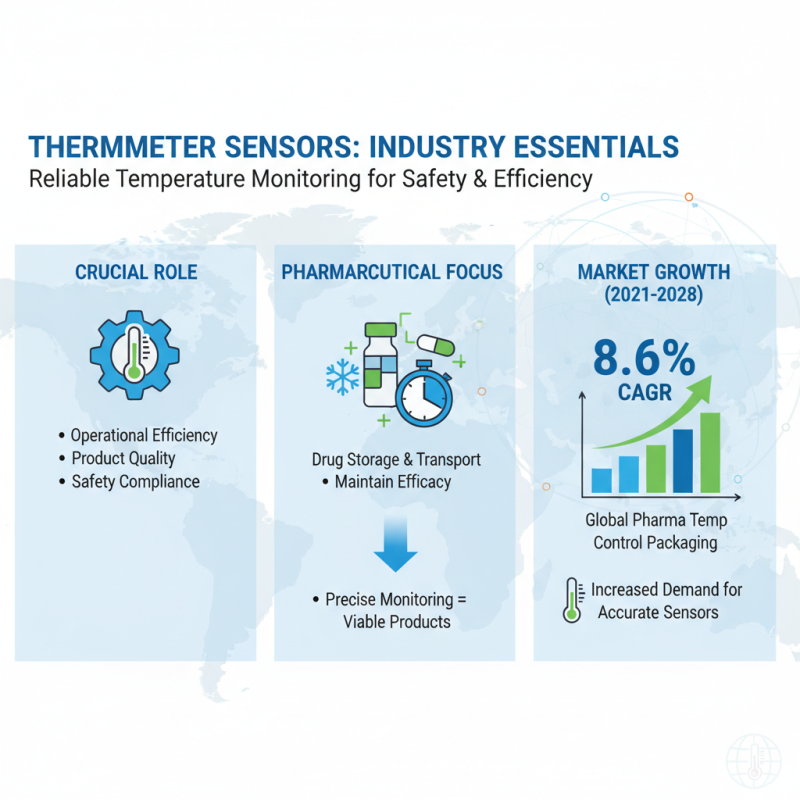

Thermometer sensors play a crucial role across a variety of industries, providing reliable temperature measurements essential for operational efficiency and safety. In the pharmaceutical industry, for example, maintaining specific temperature ranges is vital during drug storage and transportation, ensuring the efficacy of products. A report from the Global Pharmaceutical Temperature Control Packaging Market predicts that the demand for temperature-controlled solutions will grow significantly, with an estimated CAGR of 8.6% from 2021 to 2028. This trend highlights the need for precise thermometer sensors to monitor conditions constantly.

In the food and beverage sector, thermometer sensors are indispensable for both safety and quality control. The FDA emphasizes the importance of keeping food at safe temperatures to prevent foodborne illnesses. According to a recent industry analysis, the global food temperature monitoring market is projected to reach $1.2 billion by 2024, underscoring the significant demand for advanced sensing technologies. Thermometer sensors are utilized in various applications, from temperature-controlled storage facilities to real-time monitoring during transportation, ensuring that products remain within safe temperature thresholds throughout the supply chain.

Furthermore, in manufacturing processes, maintaining the optimal temperature is essential for product quality and machine efficiency. Thermometer sensors assist in managing heat-sensitive processes, reducing waste and increasing yield. An industry report indicated that the integration of temperature monitoring solutions in manufacturing could improve efficiency by up to 30%. This illustrates the critical role that thermometer sensors play in enhancing productivity and reliability in diverse industrial applications.

Challenges and Innovations in Thermometer Sensor Technology

The advancements in thermometer sensor technology present both challenges and innovations that drive the industry forward. As the demand for precision in measurement increases across various fields, including healthcare, environmental monitoring, and industrial processes, traditional thermometer sensors are pushed to their limits. One of the primary challenges lies in enhancing the accuracy and response time of these sensors to maintain reliability in critical applications. For instance, in medical settings, any delay in temperature readings could impede patient care, underscoring the need for faster and more dependable devices.

Innovations in materials and fabrication techniques have spawned the development of advanced sensors that offer enhanced functionalities. For example, the integration of microelectromechanical systems (MEMS) allows for reduced size and increased sensitivity in thermometer sensors. This technology not only improves performance but also expands the range of applications, such as wearable health devices and smart home systems. As these innovations permeate the market, users can expect sensors capable of real-time data transmission and improved diagnostics capabilities.

**Tips**: When selecting a thermometer sensor for specific applications, consider the required accuracy and response time. It's also essential to keep an eye on emerging technologies that could enhance sensor performance in the future. Additionally, regular calibration and maintenance of sensors ensure optimal operation and longevity, which is crucial for critical measurements.

Related Posts

-

7 Best Thermometer Sensors for Accurate Temperature Monitoring in Various Applications

-

Top 5 Best Temperature Probe Sensors for Accurate Cooking and Brewing

-

Top Strategies for Enhancing Efficiency with Temperature Monitoring Sensors

-

Top Strategies for Maximizing Efficiency with Temperature Detectors

-

5 Essential Tips for Choosing the Right Temperature Sensor for Your Business Needs

-

Understanding Temp Sensors: How They Revolutionize Modern Climate Control Systems