What is a Temperature Sensor and How Does It Work?

Temperature sensors play a crucial role in various industries. They are vital for monitoring and controlling temperature in countless applications. According to a recent report by Markets and Markets, the global temperature sensor market is projected to reach $6.88 billion by 2025, growing at a CAGR of 5.9%. This growth highlights their importance in sectors such as manufacturing, healthcare, and environmental monitoring.

Temperature sensors work by measuring the temperature of an object or environment. Common types include thermocouples, thermistors, and infrared sensors. Each type has its strengths and weaknesses. For instance, thermocouples can measure high temperatures but can be less accurate than thermistors. The choice of sensor can significantly impact the effectiveness of temperature monitoring systems.

Despite their strengths, temperature sensors are not without challenges. Calibration issues can lead to inaccuracies. Environmental factors can also affect their performance. Understanding these limitations is essential for achieving optimal results. By addressing these concerns, industries can improve processes and ensure safety.

Definition of a Temperature Sensor and Its Importance

Temperature sensors are crucial devices used to measure temperature accurately. These sensors come in various types, like thermocouples, thermistors, and infrared sensors. Each type has its unique properties, making them suitable for different applications. Knowing how they work helps in choosing the right sensor for a specific need.

The importance of a temperature sensor cannot be overstated. In industrial settings, they monitor processes to ensure safety. In healthcare, they help track patient conditions. The failure of these sensors can lead to significant issues. A malfunctioning temperature sensor can result in equipment damage or incorrect medical treatments. It is vital to test and calibrate these sensors regularly. Do they always perform accurately? Perhaps not, and we must address these concerns diligently.

Temperature Sensor Performance Data

This bar chart displays the temperature measurements from various temperature sensors. The data indicates the recorded temperatures, allowing for comparison of sensor performance and accuracy.

Types of Temperature Sensors and Their Applications

Temperature sensors play a crucial role in various applications. There are several types, each suited for different needs. Thermocouples are popular in industrial settings for their wide temperature range. They work by producing a voltage when two different metals are joined. This voltage changes based on temperature.

Thermistors, on the other hand, are sensitive resistors. They are often found in medical equipment. Their resistance changes significantly with temperature. This feature makes them ideal for precise readings in critical applications. Infrared sensors detect radiation from objects, making them useful for temperature checks without contact.

These sensors all have specific uses but can also face challenges. For example, thermocouples may drift over time, leading to inaccurate readings. Additionally, choosing the right sensor requires understanding the environment. Temperature extremes, humidity, and interference can affect their performance. Balancing accuracy and cost is essential for optimal results.

How Temperature Sensors Function: A Detailed Explanation

Temperature sensors are essential in many industries, from manufacturing to healthcare. They measure temperature with high precision, which is crucial for various applications. These sensors can operate based on different principles, such as thermocouples, thermistors, and infrared technology.

Thermocouples are widely used due to their ruggedness and wide temperature range. They can measure temperatures from -200 to 1,800 degrees Celsius. However, their accuracy can vary, leading to potential errors in critical applications. Meanwhile, thermistors respond quickly to temperature changes, making them suitable for medical devices. Their sensitivity can reach a point where minor temperature fluctuations are detected, but this can also cause instability if not calibrated properly.

A market report from Research and Markets indicates that the global temperature sensor market is expected to grow significantly, reaching USD 5 billion by 2027. This growth reflects an increasing demand for accurate temperature monitoring. Despite advancements, some sensors still struggle with response time and drift issues. Continuous improvements are necessary to enhance their reliability.

What is a Temperature Sensor and How Does It Work?

| Sensor Type | Working Principle | Temperature Range (°C) | Accuracy | Applications |

|---|---|---|---|---|

| Thermocouple | Measures voltage difference between two dissimilar metals | -200 to 1800 | ±1.5% of Reading | Industrial processes, furnaces |

| RTD (Resistance Temperature Detector) | Resistance change in metal with temperature | -200 to 850 | ±0.1 to ±0.5 °C | Laboratories, food processing |

| Thermistor | Resistance decreases with increase in temperature | -55 to 125 | ±0.2 to ±0.5 °C | Medical devices, automotive |

| Infrared Sensor | Measures emitted infrared radiation | -50 to 1000 | ±1.5% of Reading | Building inspections, non-contact temperature measurement |

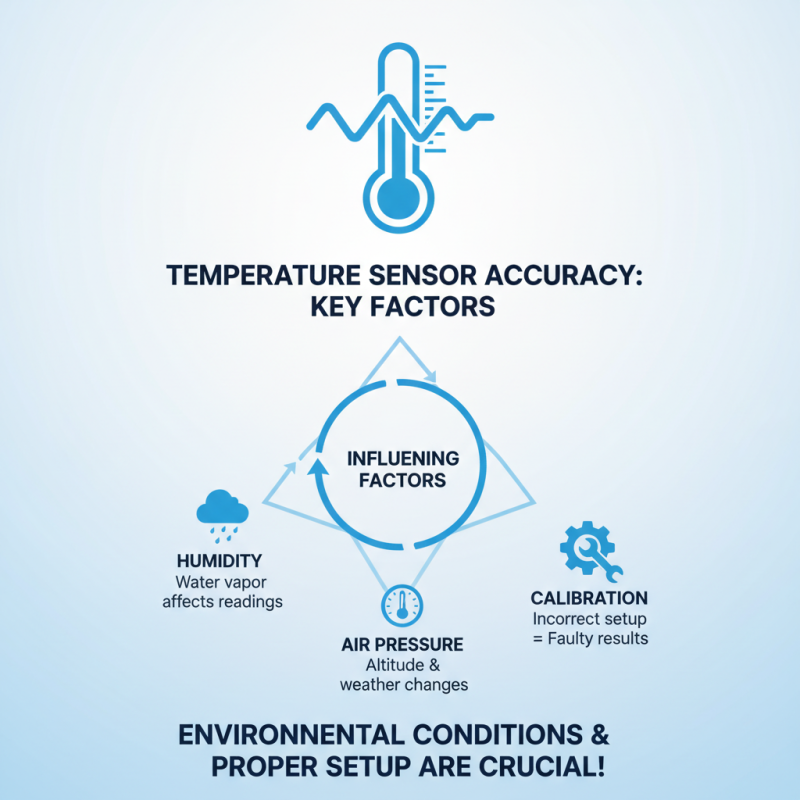

Factors Affecting Temperature Sensor Performance and Accuracy

Temperature sensors are essential in many applications. Their accuracy and performance can be influenced by several factors. Environmental conditions play a significant role. For example, humidity and air pressure can affect readings. If a sensor is not calibrated correctly, it may give faulty results.

Material properties of the sensor are crucial as well. Different materials respond to temperature changes at varying rates. For instance, metal sensors often react faster than plastic ones. Additionally, the design and placement of the sensor matter. A poorly placed sensor may read temperatures inaccurately due to proximity to heat sources or drafts.

Another aspect is aging. Over time, sensors can drift from their original specifications. Regular maintenance and calibration are necessary. However, this can be overlooked in many cases, leading to potential inaccuracies. Each of these factors must be considered to ensure that temperature readings are reliable.

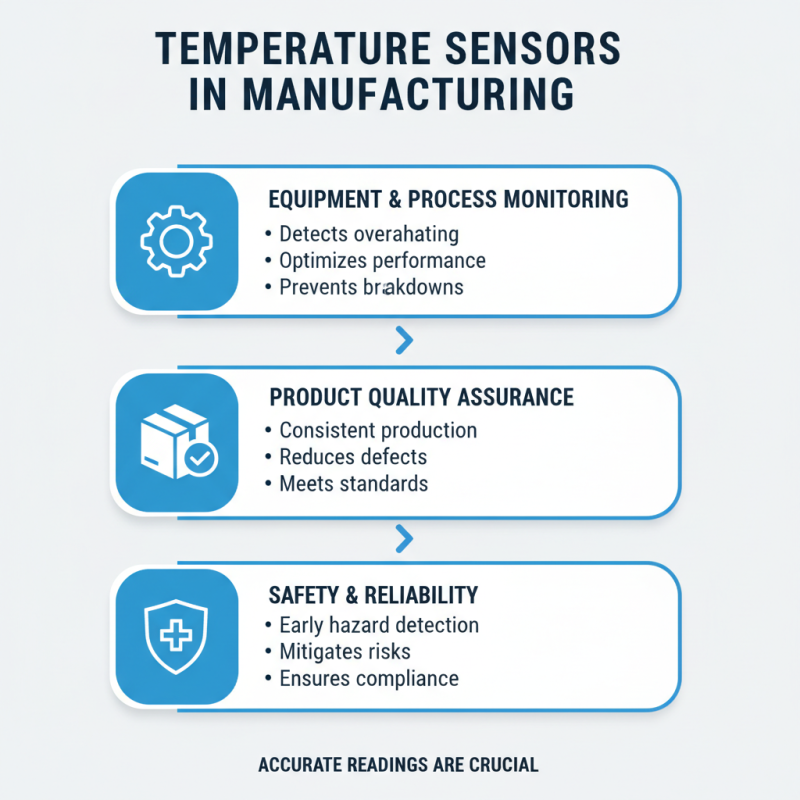

Applications of Temperature Sensors in Various Industries

Temperature sensors play a vital role across diverse industries. In manufacturing, they monitor equipment and processes. Accurate temperature readings ensure product quality. A slight deviation can lead to defects or even safety issues.

In the medical field, temperature sensors are essential. They help track body temperatures in patients. Hospitals rely on them for early detection of infections. However, maintaining calibration can be challenging. Inaccuracies may lead to misdiagnosis or delayed treatment.

Food safety is another critical application. Temperature sensors monitor conditions during food storage. They help prevent spoilage and ensure compliance with safety standards. Yet, not all sensors are reliable. Regular checks and maintenance are crucial to avoid health risks.

Related Posts

-

What is the Best Temp Sensor for Your Needs?

-

Understanding Temp Sensors: How They Revolutionize Modern Climate Control Systems

-

5 Essential Tips for Choosing the Right Temperature Sensor for Your Business Needs

-

Understanding How Temperature Probe Sensors Revolutionize Home Cooking and Food Safety

-

Top Strategies for Enhancing Efficiency with Temperature Monitoring Sensors

-

10 Best High Temperature Sensors for Accurate Measurements in 2023