Unlocking the Power of Omega Heat Flux Sensors for Energy Efficiency in Modern Technology

In the quest for enhanced energy efficiency, the role of advanced technologies cannot be overstated, particularly when it comes to monitoring and optimizing thermal performance.

The omega heat flux sensor stands out as a pivotal tool in this domain, enabling precise measurement of heat flow across various materials and systems.

According to a recent report from the International Energy Agency (IEA), achieving a 30% improvement in energy efficiency in industrial processes alone could yield annual savings of over $600 billion globally.

By incorporating cutting-edge sensors like the omega heat flux sensor, industries can obtain real-time data that informs better decision-making and fosters sustainable practices.

This not only contributes to reduced operational costs but also aligns with international sustainability goals by minimizing energy waste.

As we explore the transformative impact of these sensors, it becomes clear that they are an essential component in the evolution of energy-efficient technologies.

The omega heat flux sensor stands out as a pivotal tool in this domain, enabling precise measurement of heat flow across various materials and systems.

According to a recent report from the International Energy Agency (IEA), achieving a 30% improvement in energy efficiency in industrial processes alone could yield annual savings of over $600 billion globally.

By incorporating cutting-edge sensors like the omega heat flux sensor, industries can obtain real-time data that informs better decision-making and fosters sustainable practices.

This not only contributes to reduced operational costs but also aligns with international sustainability goals by minimizing energy waste.

As we explore the transformative impact of these sensors, it becomes clear that they are an essential component in the evolution of energy-efficient technologies.

The Importance of Omega Heat Flux Sensors in Energy Management

Omega heat flux sensors play a pivotal role in energy management systems, providing critical data that enhances efficiency and reduces waste. According to a report by the American Institute of Chemical Engineers (AIChE), implementing accurate heat flux measurements can improve energy efficiency by up to 30% in industrial applications. These sensors enable real-time monitoring of thermal energy transfer, allowing organizations to adjust processes dynamically, thereby optimizing energy consumption.

Furthermore, the U.S. Department of Energy states that about 29% of energy consumed in the industrial sector is lost as waste heat. By employing Omega heat flux sensors, businesses can identify specific heat losses and implement strategies to recover this waste. This not only leads to significant cost savings but also supports sustainability initiatives by reducing the carbon footprint associated with excessive energy use. The data provided by these sensors empowers facility managers to make informed decisions, driving continuous improvements in their energy management practices.

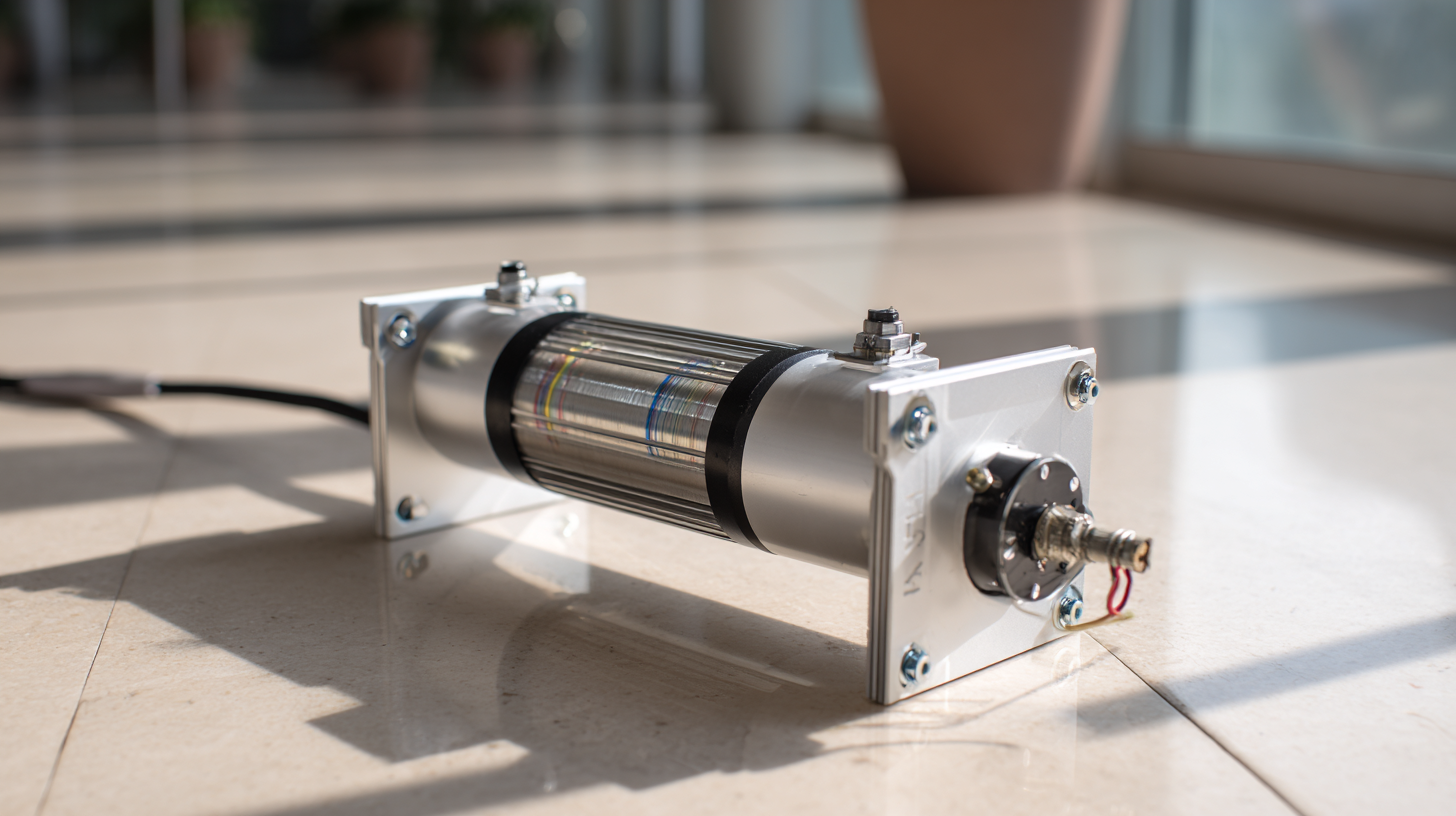

How Omega Heat Flux Sensors Work: Technology Behind the Efficiency

Omega heat flux sensors are pivotal in enhancing energy efficiency across various technological applications. These sensors operate on the principle of measuring heat transfer through a specific surface area, providing real-time data on thermal energy movement. By utilizing thermoelectric materials, these sensors detect temperature gradients, allowing for precise calculations of heat flux. This accuracy is crucial for systems that require diligent monitoring of thermal dynamics, such as HVAC systems, building insulation assessments, and electronic device cooling solutions.

Omega heat flux sensors are pivotal in enhancing energy efficiency across various technological applications. These sensors operate on the principle of measuring heat transfer through a specific surface area, providing real-time data on thermal energy movement. By utilizing thermoelectric materials, these sensors detect temperature gradients, allowing for precise calculations of heat flux. This accuracy is crucial for systems that require diligent monitoring of thermal dynamics, such as HVAC systems, building insulation assessments, and electronic device cooling solutions.

The technology behind Omega heat flux sensors embodies advanced thermodynamic principles, making them an essential tool in modern energy management. By integrating these sensors into systems, engineers can identify inefficiencies in energy usage and make informed decisions to optimize performance. Furthermore, the data gathered facilitates the development of innovative materials and techniques aimed at preserving energy, thereby contributing to sustainability efforts in various industries. Ultimately, Omega heat flux sensors not only enhance operational efficiency but also promote a deeper understanding of energy flows in contemporary technology.

Applications of Omega Heat Flux Sensors in Various Industries

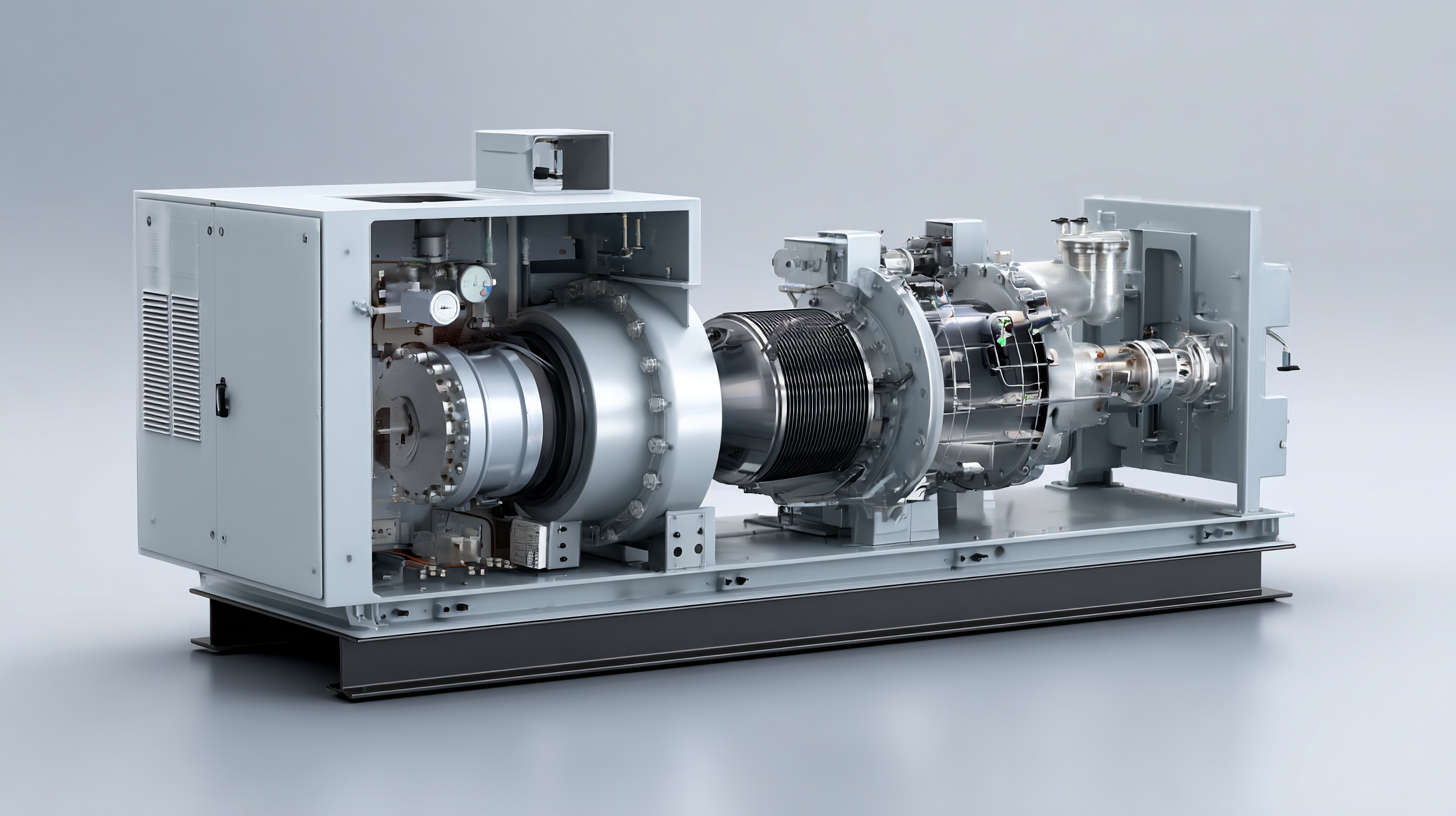

Omega heat flux sensors have become integral to various industries, providing critical insights into energy usage and efficiency. In the manufacturing sector, these sensors allow for the real-time monitoring of heat transfer processes, which is essential for optimizing operational efficiency and reducing energy wastage. By accurately measuring the heat flux in processes such as welding and casting, companies can make informed adjustments that enhance productivity while minimizing thermal losses.

In the realm of building management, Omega heat flux sensors contribute significantly to energy conservation efforts. By integrating these sensors within HVAC systems, facilities can monitor and control heat transfer in real-time, leading to more efficient temperature regulation. This capability not only reduces energy consumption but also improves occupant comfort.

Additionally, in renewable energy applications, such as solar thermal systems, these sensors facilitate the monitoring of heat absorption and transfer, ensuring that systems operate at peak efficiency and contribute effectively to sustainable energy goals.

Benefits of Integrating Omega Heat Flux Sensors for Sustainable Practices

The integration of Omega heat flux sensors into modern technology offers a range of benefits that significantly advance sustainable practices. These sensors provide precise measurements of heat transfer, enabling industries to monitor and optimize energy usage with unparalleled accuracy. By harnessing this data, companies can identify heat loss in processes, machinery, and buildings, leading to actionable insights that promote energy efficiency. This not only reduces operational costs but also minimizes the carbon footprint associated with energy consumption.

Moreover, the implementation of Omega heat flux sensors plays a vital role in developing innovative solutions for renewable energy applications. For instance, in solar panel technology, these sensors help in maximizing energy capture by measuring temperature differentials and adjusting system operations accordingly. Additionally, in the context of construction and architecture, integrating these sensors can ensure that buildings are designed for optimal thermal performance, contributing to long-term energy savings and sustainability. Overall, the strategic use of Omega heat flux sensors in various sectors fosters a culture of environmental responsibility while driving technological advancements.

Future Trends in Omega Heat Flux Sensor Technology and Energy Efficiency

As modern technology continues to evolve, the integration of Omega heat flux sensors is becoming increasingly essential for enhancing energy efficiency. These sensors measure the heat transfer rate across surfaces, providing crucial data that can be used to optimize various processes in industries ranging from manufacturing to building management. The future trends indicate that the application of Omega heat flux sensors will expand, with advancements in sensor technology leading to more accurate and real-time data collection. This will allow organizations to implement smarter energy management strategies, reducing waste and lowering operational costs.

Tips for enhancing the use of Omega heat flux sensors include regularly calibrating sensors to ensure accuracy and reliability. It's also beneficial to analyze data trends over time, as this can reveal patterns that indicate potential energy savings. Additionally, integrating these sensors with IoT devices can enhance monitoring capabilities, allowing for automated responses to changing thermal conditions in real-time.

Looking ahead, we anticipate a surge in the development of wireless heat flux sensors, making installation easier and reducing infrastructural constraints. This innovation will likely advance remote monitoring capabilities, enabling businesses to characterize energy usage more efficiently. As these sensors become more accessible and affordable, their widespread adoption could significantly contribute to a more sustainable future.

Unlocking the Power of Omega Heat Flux Sensors for Energy Efficiency in Modern Technology - Future Trends in Omega Heat Flux Sensor Technology and Energy Efficiency

| Parameter | Current Value | Future Trend | Impact on Energy Efficiency |

|---|---|---|---|

| Sensor Sensitivity | High | Ultra-sensitive | Improved accuracy in energy measurement |

| Response Time | Fast (milliseconds) | Instantaneous | Real-time optimization of energy consumption |

| Integration Capability | Moderate | Seamless (IoT ready) | Facilitates smart energy solutions |

| Material Durability | Standard | Enhanced | Longer lifespan reduces replacement frequency |

| Cost | Moderate | Affordable | Wider adoption in various industries |

Related Posts

-

What is a Soil Temperature Probe and How Does it Enhance Agricultural Productivity

-

7 Secrets to Choosing the Best High Temperature Sensor for Industrial Applications

-

Understanding Thermal Conductivity Testing for Enhanced Material Performance

-

Exploring the Future of Water Quality: How Conductivity Sensors Enhance Environmental Monitoring

-

Ultimate Guide to Mastering Thermal Conductivity Sensors for Enhanced Performance

-

Understanding the Impact of Thermal Sensors on Smart Technology Integration