Why Heat Flux Sensors Are Essential for Accurate Thermal Measurements

In today's fast-paced technological environment, accurate thermal measurements are crucial across various industries, from aerospace to renewable energy. At the core of these measurements lies the heat flux sensor, an indispensable tool that quantifies the rate of heat transfer through a given surface. According to a recent report by MarketsandMarkets, the global heat flux sensor market is expected to grow significantly, reaching USD 5.2 billion by 2025, driven by advancing technologies and increased demand for precision in thermal management.

Heat flux sensors play a vital role in enhancing energy efficiency, improving product design, and ensuring safety in high-temperature applications. For instance, in aerospace engineering, accurate thermal readings are paramount for testing materials' endurance and performance under extreme conditions. Furthermore, the increasing focus on sustainability and energy conservation in industries like HVAC (heating, ventilation, and air conditioning) has led to a heightened reliance on heat flux sensors to optimize energy consumption and reduce costs.

Heat flux sensors play a vital role in enhancing energy efficiency, improving product design, and ensuring safety in high-temperature applications. For instance, in aerospace engineering, accurate thermal readings are paramount for testing materials' endurance and performance under extreme conditions. Furthermore, the increasing focus on sustainability and energy conservation in industries like HVAC (heating, ventilation, and air conditioning) has led to a heightened reliance on heat flux sensors to optimize energy consumption and reduce costs.

The precision offered by heat flux sensors not only aids in meeting regulatory standards but also fosters innovation by facilitating the development of cutting-edge thermal technologies. As the industry continues to evolve, the integration of advanced heat flux sensor technologies will be instrumental in driving efficiency and reliability in thermal measurements, thereby underscoring their essential role in modern engineering applications.

The Importance of Heat Flux Sensors in Thermal Analysis

Heat flux sensors play a pivotal role in thermal analysis by providing precise measurements of heat transfer rates. These sensors are designed to monitor how much thermal energy flows through a given area, making them essential for applications ranging from building energy efficiency evaluations to industrial process optimizations. Accurate thermal measurements are crucial, as they influence material performance, energy consumption, and overall system efficiency.

Tip: When selecting heat flux sensors, consider the environment in which they will be used. Factors such as temperature range, material compatibility, and response time can significantly impact measurement accuracy.

In thermal analysis, data from heat flux sensors help engineers and scientists understand energy interactions and optimize designs. By integrating these sensors into experimental setups, high-resolution thermal profiles can be obtained, facilitating better decision-making in both product development and system configuration. The insights gained can lead to enhanced energy savings and improved safety measures in various applications.

Tip: Regular calibration of heat flux sensors ensures ongoing accuracy and reliability in measurements, which is vital for long-term projects and critical applications.

Key Applications of Heat Flux Sensors in Various Industries

Heat flux sensors play a crucial role in accurately measuring thermal energy transfer across various applications in multiple industries. In sectors like construction, automotive, and aerospace, these sensors ensure effective thermal management by providing precise data on heat flow. For instance, in building thermography, heat flux sensors help identify areas of energy loss, enabling improved insulation and energy efficiency. The automotive industry utilizes these sensors to monitor engine temperatures and optimize performance, which is essential for both efficiency and safety.

Moreover, as the demand for innovation and energy efficiency grows, the market for dual pressure and temperature sensors is projected to expand significantly. The market size is estimated to reach $4.44 billion by 2024, with a remarkable compound annual growth rate of 24.3%, expected to rise to $31.2 billion by 2033. This surge in growth reflects the increasing need for advanced thermal measurement tools across various fields, demonstrating how integral heat flux sensors are in driving forward technologies and enhancing operational efficiencies in industrial applications.

Thermal Measurement Accuracy in Various Industries

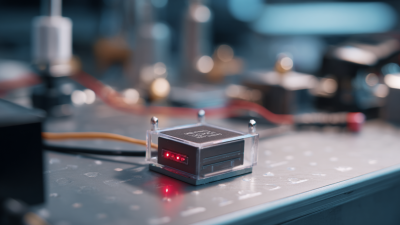

Technological Advancements in Heat Flux Sensor Design

Recent technological advancements in heat flux sensor design have significantly enhanced the accuracy and reliability of thermal measurements. Traditionally, heat flux sensors have faced challenges related to calibration, response time, and sensitivity. However, innovations such as miniaturized sensor components and improved materials have resolved these issues, allowing for real-time monitoring with greater precision.

New sensor designs incorporate advanced thermoelectric materials, which enable rapid detection of temperature differentials and provide more accurate heat flux readings across various applications.

New sensor designs incorporate advanced thermoelectric materials, which enable rapid detection of temperature differentials and provide more accurate heat flux readings across various applications.

Furthermore, the integration of smart technology into heat flux sensors has transformed data collection and analysis. Wireless capabilities and IoT integration allow for seamless data transmission and remote monitoring, making it easier to collect and analyze thermal data in real-time. This connectivity facilitates more extensive data sets, enabling engineers and researchers to undertake more robust thermal analysis.

These advancements not only improve the operational efficiency of thermal measurement systems but also expand their utility in diverse fields, from aerospace engineering to building energy management.

Challenges in Thermal Measurement and How Heat Flux Sensors Address Them

Thermal measurement plays a critical role across various industries, yet it presents numerous challenges. Environmental factors, such as ambient temperature variations and surface conditions, can lead to inaccuracies in traditional measurement methods. These inaccuracies can significantly impact energy efficiency assessments and material performance evaluations. Consequently, relying solely on conventional temperature sensors often proves inadequate.

Heat flux sensors emerge as a solution to these challenges by providing direct measurements of heat transfer. Unlike standard temperature sensors, which only capture static data, heat flux sensors record dynamic thermal properties in real-time. This capability allows for a more precise understanding of thermal profiles and energy losses, ultimately enhancing the effectiveness of thermal management practices.

Tips: To ensure optimal performance of heat flux sensors, consider calibrating them regularly to maintain accuracy. Additionally, pay attention to the installation process, as proper placement and thermal contact are essential for reliable data collection. Lastly, integrating heat flux sensors with advanced data analytics can further enhance insight into thermal behaviors and improve decision-making in thermal management strategies.

Future Trends in Heat Flux Sensing Technology for Enhanced Accuracy

The evolution of heat flux sensing technology is paving the way for enhanced accuracy in thermal measurements across various industries. As the demand for precise thermal management grows, advancements in sensor materials and design are making it possible to achieve higher sensitivity and faster response times. Emerging techniques, such as the integration of nanotechnology and advanced signal processing algorithms, are leading to sensors that can operate effectively in diverse environments while providing real-time data. These innovations promise improved reliability and reduced noise in thermal readings, addressing the challenges faced by traditional sensors.

Moreover, the future of heat flux sensing technology is poised to incorporate smart features that leverage the Internet of Things (IoT) for enhanced connectivity and usability. Sensors capable of transmitting data wirelessly can facilitate immediate analysis and remote monitoring, allowing for proactive thermal management strategies.

As industries shift toward automated systems, the importance of these intelligent heat flux sensors will only increase, ensuring that precise thermal measurements support the development of efficient systems and products. The integration of AI-driven analytics is also expected to optimize the performance of heat flux sensors, interpreting complex thermal data more effectively and helping to inform critical decision-making processes.

Related Posts

-

Unlocking the Power of Omega Heat Flux Sensors for Energy Efficiency in Modern Technology

-

Exploring Innovative Applications of Thermal Conductivity Sensors in Modern Technology

-

How to Choose the Right Thermal Conductivity Meter for Your Application

-

Top Strategies for Maximizing Efficiency with Temperature Detectors

-

Challenges Faced by Industries Using Temperature Monitoring Sensors

-

Innovative Applications of Omega Heat Flux Sensors in Modern Industries