10 Essential Tips to Improve Thermal Conductivity of Materials in Your Projects

When embarking on projects that involve the manipulation of materials, understanding the thermal conductivity of materials becomes essential for achieving desired outcomes. Thermal conductivity refers to the ability of a material to conduct heat, and it plays a crucial role in a variety of applications, from insulation solutions in construction to efficient heat dissipation in electronic devices. By effectively managing thermal conductivity, project managers and engineers can enhance performance, improve energy efficiency, and ensure safety across various implementations.

In this guide, we will explore ten essential tips aimed at improving the thermal conductivity of materials used in your projects. Each tip provides actionable insights that can help you select the right materials, optimize their properties, and implement innovative strategies for thermal management. Whether you are involved in designing advanced thermal systems or simply seeking to upgrade existing materials for better heat transfer, understanding these principles will arm you with the knowledge needed to enhance your project's success.

Understanding Thermal Conductivity and Its Importance in Material Science

Thermal conductivity is a fundamental property of materials that dictates how efficiently they can conduct heat. It plays a crucial role in various engineering applications, from electronics to construction, where managing heat flow is essential for performance and safety. Understanding thermal conductivity helps engineers select the right materials to enhance energy efficiency, maintain desired temperatures, and prevent material failure due to heat-related stresses. A report from the Department of Energy highlights that improving thermal management in buildings could lead to energy savings of up to 30% annually, emphasizing the economic significance of choosing materials with optimal thermal properties.

In material science, thermal conductivity is often expressed in watts per meter-kelvin (W/m·K), indicating how much heat passes through a material over a given distance for a temperature difference of one degree. This property is influenced by several factors, including material composition, structure, temperature, and moisture content. According to a study published in the Journal of Materials Science, the thermal conductivity of common construction materials—such as concrete, wood, and insulation—varies widely, with insulated materials having conductivity values as low as 0.03 W/m·K. This variation underscores the importance of selecting appropriate materials tailored to specific applications to optimize thermal performance and drive innovation in product design.

10 Essential Tips to Improve Thermal Conductivity of Materials in Your Projects

| Tip Number | Tip Description | Material Examples | Typical Applications |

|---|---|---|---|

| 1 | Select materials with high intrinsic thermal conductivity. | Copper, Silver | Electrical wiring, heat sinks |

| 2 | Use composite materials to enhance thermal performance. | Graphite-filled polymers | Heat exchangers, automotive parts |

| 3 | Optimize the thickness of materials for conduction efficiency. | Aluminum sheets | Insulation layers, cooking pans |

| 4 | Increase surface area for better thermal exchange. | Finned surfaces | Radiators, air coolers |

| 5 | Implement thermal treatments to enhance microstructure. | Heat-treated steels | Industrial machinery, automotive |

| 6 | Use fillers and additives to enhance thermal conductivity. | Carbon nanotubes, metal oxides | Thermal pastes, adhesives |

| 7 | Use insulation materials carefully to avoid thermal barriers. | Aerogels, ceramic fibers | High-temperature applications, cryogenics |

| 8 | Consider phase change materials for thermal regulation. | Paraffin wax, salt hydrates | Building materials, thermal storage |

| 9 | Employ proper bonding methods to reduce thermal interface resistance. | Thermal interface materials (TIMs) | Electronics cooling, LED applications |

| 10 | Regularly evaluate and test thermal performance of materials. | Testing equipment and sensors | Quality control, R&D |

Factors Affecting Thermal Conductivity in Various Materials

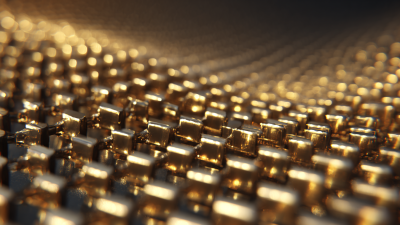

Thermal conductivity is a crucial property that determines how well materials can conduct heat, significantly impacting their performance in various applications. Several factors influence this conductivity, including material composition, structure, and environmental conditions. For instance, metals generally exhibit high thermal conductivity due to their free electrons, which facilitate efficient heat transfer. In contrast, insulating materials like ceramics or polymers have lower conductivity, often due to their covalent or ionic bonds that restrict electron movement.

Another pivotal aspect affecting thermal conductivity is the physical structure of the material. For example, crystalline structures, which allow atoms to be arranged in an orderly manner, typically enhance thermal conductivity compared to amorphous structures. Additionally, the presence of voids or porosity within a material can impede heat flow, as these air-filled spaces act as barriers to thermal transfer. Environmental factors such as temperature and pressure also play a significant role; for instance, increasing temperature can improve the mobility of charge carriers in a material, enhancing its conductivity. Understanding these factors enables engineers and researchers to devise strategies to optimize thermal performance across various materials in their projects.

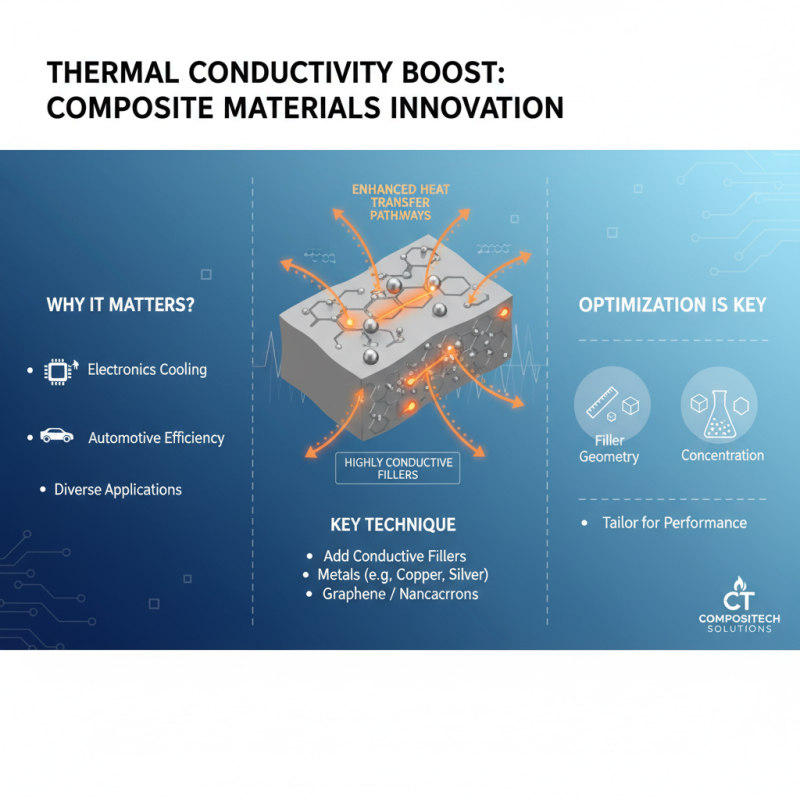

Techniques for Enhancing Thermal Conductivity in Composite Materials

Enhancing thermal conductivity in composite materials is crucial for a wide range of applications, from electronics to automotive engineering. One effective technique is the incorporation of highly conductive fillers, such as metals or graphene, into the matrix. These additives can significantly improve heat transfer by providing pathways for thermal energy to flow through the composite. Careful selection and optimization of these fillers based on their geometry and concentration can lead to marked improvements in overall thermal performance.

Another method for enhancing thermal conductivity is to manipulate the fabrication process itself. Utilizing techniques like hot pressing or sintering can help achieve better interfacial bonding between the filler and matrix, facilitating efficient thermal transfer. Additionally, controlling the curing temperature and time can help align the filler particles in ways that further enhance conductivity.

Incorporating surface treatments or coatings on the filler materials can also yield positive results. This approach not only improves compatibility with the polymer matrix but can also enhance the interaction between particles, leading to an increase in thermal pathways. By exploring these techniques and staying informed on the latest advancements, engineers can effectively boost the thermal conductivity of composite materials in their projects.

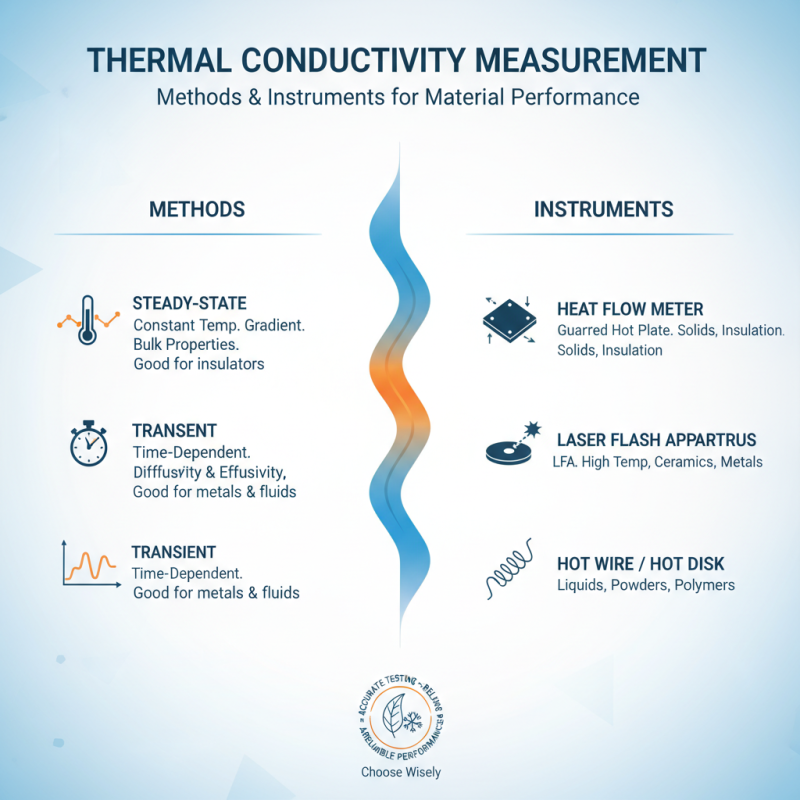

Measuring and Testing Thermal Conductivity of Materials Accurately

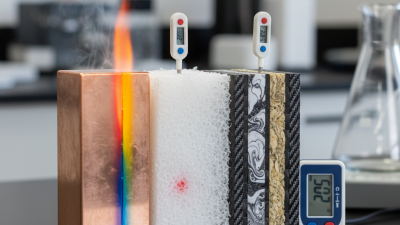

Accurate measurement and testing of thermal conductivity are crucial for assessing material performance in various applications. To achieve reliable results, it’s essential to use the right methods and instruments tailored to the material types you’re working with. For instance, employing steady-state or transient methods can yield different insights depending on the sample's characteristics and the environment.

When conducting thermal conductivity tests, ensure that the material sample is representative of the final product. Consistency in sample preparation, including dimensions and temperature conditions, plays a vital role in minimizing errors. Additionally, calibrate your testing equipment regularly to maintain precision throughout the testing process.

To further improve thermal conductivity in your projects, consider optimizing your material selection. Choosing materials with inherently high thermal conductivity can lead to superior performance. Additionally, blending materials or incorporating additives might enhance the overall conductivity, offering potential improvements in thermal management. Pay close attention to the microstructure of the materials, as this can significantly impact their thermal performance.

Applications of Improved Thermal Conductivity in Engineering Projects

Improving thermal conductivity in engineering projects can significantly enhance efficiency and performance across various applications. High thermal conductivity materials are essential in systems where heat transfer plays a crucial role, such as in electronics cooling, aerospace applications, and energy-efficient building materials. By utilizing materials with improved thermal properties, engineers can optimize systems for better heat dissipation and energy conservation.

One effective tip to enhance thermal conductivity is to incorporate composite materials that combine high-performance compounds. These composites can leverage the advantages of each component, resulting in materials that outperform traditional metals or ceramics. Additionally, ensuring proper alignment of particles in these composites can further enhance their thermal transfer capabilities, which is vital in applications like heat exchangers or thermal interface materials.

Another approach is to enhance the surface area of materials. Techniques such as nanostructuring or adding porous elements can facilitate increased heat transfer by providing more pathways for thermal conduction. This is particularly applicable in applications like insulation systems, where maximizing heat distribution is essential. By employing these methods, engineers can create innovative solutions that meet the demands of modern thermal management challenges in their projects.

Related Posts

-

What is Thermal Conductivity of Materials Explained with Examples and Applications

-

7 Best Materials with Exceptional Thermal Conductivity You Should Know

-

Understanding the Impact of Thermal Conductivity on Material Selection in Engineering

-

How to Choose the Right Thermal Conductivity Meter for Your Application

-

Understanding the Thermal Conductivity of Materials: Key Factors and Measurements

-

Unlocking Opportunities in Conductivity Measurement at the 2025 China Import and Export Fair Industry Insights and Trends