Best Thermal Conductivity Sensors for Accurate Temperature Measurements

In the realm of temperature measurement, the accuracy and reliability of data are paramount, particularly in industries where precise thermal management is critical. As technology advances, the need for better tools becomes evident, leading to an increased interest in thermal conductivity sensors. These sensors not only measure temperature but also provide insights into the thermal properties of materials, making them invaluable across various applications. According to Dr. Emily Carter, a leading expert in thermal science, "The development and implementation of high-precision thermal conductivity sensors have revolutionized our ability to monitor and control thermal environments."

As industries evolve and face new challenges, traditional temperature measurement methods often fall short. Thermal conductivity sensors offer a sophisticated solution, enabling engineers and scientists to gather detailed thermal data effectively. This innovation is essential for improving energy efficiency, optimizing thermal performance, and ensuring product reliability. Dr. Carter emphasizes the transformative potential of these sensors, stating that "By utilizing advanced thermal conductivity measurements, we can push the boundaries of thermal management technologies further than ever before."

Navigating the landscape of thermal conductivity sensors requires an understanding of their mechanisms and applications. Addressing this need for knowledge, this article will explore the best thermal conductivity sensors available today, focusing on their features, performance, and ideal use cases to empower professionals in making informed decisions for accurate temperature measurements.

Benefits of High Thermal Conductivity Sensors in Temperature Measurement

High thermal conductivity sensors play a pivotal role in achieving precise temperature measurements across various industries, including manufacturing, HVAC, and electronics. According to a report by the International Journal of Thermal Sciences, sensors with high thermal conductivity can result in sensitivity improvements of up to 30%, enabling more accurate readings in dynamic environments. This enhanced response time is crucial in applications where rapid temperature fluctuations occur, such as in semiconductor fabrication, where even slight deviations can lead to significant operational issues.

Moreover, the integration of advanced materials such as graphene and silicon carbide has further elevated the performance of thermal conductivity sensors. A study published in the Journal of Sensors indicates that these materials not only improve accuracy but also extend the operational lifespan of sensors, reducing maintenance costs. Businesses that prioritize high thermal conductivity sensors can benefit from improved efficiency and lower downtime, as these sensors facilitate timely decision-making in process control and energy management, leading to better overall productivity.

Types of Thermal Conductivity Sensors Used in Industry

Thermal conductivity sensors play a crucial role in various industries, ensuring accurate temperature measurements critical for process control and safety. Among the prevalent types of thermal conductivity sensors, thermocouples and resistance temperature detectors (RTDs) stand out due to their reliability and precision. According to a recent report by MarketsandMarkets, the global market for these sensors is expected to reach $5.2 billion by 2025, reflecting the rising demand for accurate temperature measurement in industrial applications.

In addition to thermocouples and RTDs, infrared thermal sensors are increasingly utilized for non-contact measurements, providing real-time data in processes where direct contact may be infeasible. The International Society of Automation highlights that infrared sensors can deliver temperature readings with an accuracy of ±0.5°C, making them indispensable in industries such as food processing and pharmaceuticals. Another notable technology is the use of fiber optic temperature sensors, which offer high sensitivity and resistance to electromagnetic interference, essential in environments with high levels of noise. With these advancements, industries can achieve enhanced process efficiency and improved safety standards.

Key Features to Consider When Selecting a Thermal Conductivity Sensor

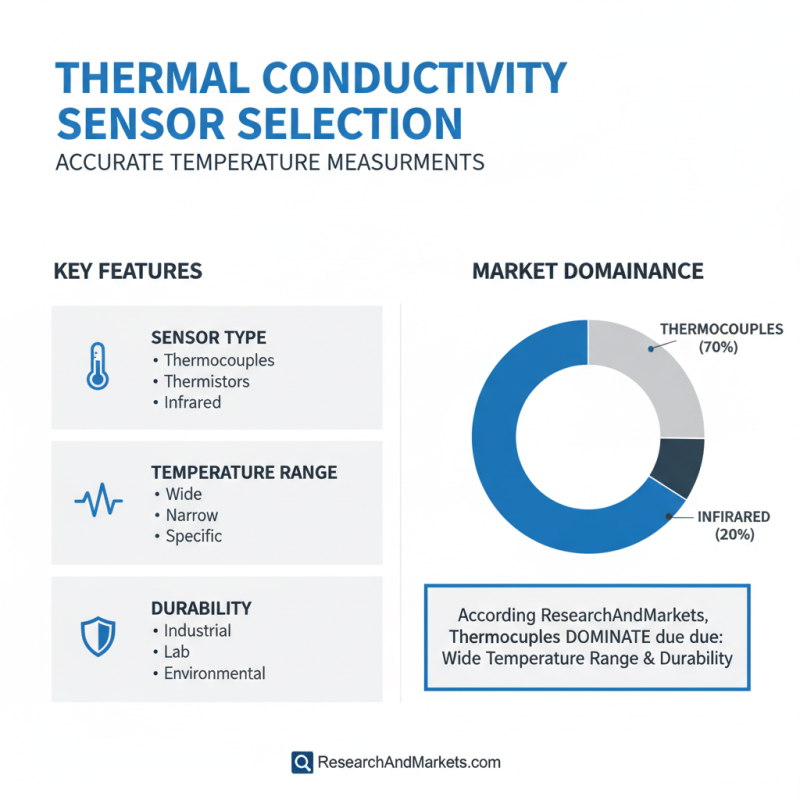

When selecting a thermal conductivity sensor for accurate temperature measurements, there are several key features to consider. Firstly, the sensor type significantly impacts performance. Common types include thermocouples, thermistors, and infrared sensors. According to a recent market analysis by ResearchAndMarkets, thermocouples dominate the market due to their wide temperature range and durability, making them suitable for various industrial applications.

Another crucial factor is sensitivity and response time. High sensitivity allows for precise temperature readings, while a fast response time ensures that measurements reflect real-time changes. A study published in the Journal of Applied Physics highlights that sensors with a response time of less than 1 second are ideal for dynamic environments. This is particularly important in processes where temperature fluctuations can affect product quality and energy efficiency.

**Tips:** When evaluating thermal conductivity sensors, prioritize those with built-in calibration features, enhancing measurement accuracy over time. Additionally, consider the environmental conditions where the sensor will be deployed; sensors rated for harsh conditions, such as extreme temperatures or humidity, will often provide more reliable results. Always consult product specifications to ensure compatibility with your specific application needs.

Applications of Thermal Conductivity Sensors in Various Fields

Thermal conductivity sensors play a pivotal role in a variety of fields, from biomaterials to electronics. Recent advancements have emerged, such as the development of flexible thin-film thermal sensors designed specifically for biomaterial applications. These sensors are capable of estimating crucial thermal transport properties which are essential in understanding the thermal behavior of biological tissues. According to industry reports, accurate temperature measurements facilitated by these sensors can significantly enhance material characterization processes.

In the realm of wearable technology, recent studies highlight the combination of MXenes with conductive polymers to improve strain sensing and thermal management. This innovation underscores the importance of thermal conductivity sensors in wearable electronics, aligning with the growing demand for more integrated and efficient sensor systems. Tips for ensuring optimal performance include maintaining calibration of sensors regularly and considering environmental factors that may affect temperature readings.

Moreover, the unique characteristics of nanostructures, such as those in mesoporous carbon materials, demonstrate further applications in energy storage and catalysis. As industries continue to explore these advanced materials, the integration of thermal conductivity sensors will be vital for monitoring and optimizing performance efficiencies, emphasizing the intersection of material science and sensor technology.

Best Thermal Conductivity Sensors for Accurate Temperature Measurements

| Sensor Type | Measurement Range (°C) | Accuracy (%) | Applications | Typical Use Cases |

|---|---|---|---|---|

| Thermal Conductivity Probe | -50 to 200 | ±0.5 | Food & Beverage | Measuring cooling rates of beverages |

| Infrared Thermal Sensor | 0 to 300 | ±1.0 | Industrial Processes | Monitoring equipment temperature |

| K-type Thermocouple | -200 to 1250 | ±1.5 | Manufacturing | Measuring high-temperature processes |

| Digital Thermal Sensor | -40 to 125 | ±0.3 | HVAC Systems | Monitoring air temperature |

| Thermal Imaging Camera | -20 to 500 | ±2.0 | Building Inspections | Identifying heat loss in structures |

Emerging Technologies in Thermal Conductivity Measurement Solutions

Emerging technologies in thermal conductivity measurement solutions are reshaping the landscape of how we understand and assess temperature-related phenomena. Recent advancements in sensor technology have led to the development of devices that not only measure thermal conductivity with unprecedented accuracy but also enhance our ability to monitor temperature fluctuations in dynamic environments. For instance, nanotechnology has paved the way for the creation of nanoscale thermal sensors that can deliver real-time data, crucial for applications ranging from biomedical monitoring to industrial processes.

Furthermore, the integration of machine learning algorithms into thermal conductivity sensors is revolutionizing data analysis and interpretation. These intelligent systems can process vast amounts of measurement data, improving predictive accuracy and enabling proactive measures in temperature management. Coupled with wireless communication technologies, these sensors can operate within the Internet of Things (IoT) frameworks, allowing seamless data transfer and remote monitoring. Such innovations not only boost efficiency but also pave the way for smarter and more connected systems across various industries, ultimately leading to more sustainable practices and enhanced safety protocols.

Best Thermal Conductivity Sensors for Accurate Temperature Measurements

This chart displays the thermal conductivity values of various sensor types used for accurate temperature measurements. The data presents the conductivity range measured in W/(m·K) for emerging sensor technologies.

Related Posts

-

Ultimate Guide to Understanding Thermal Conductivity Testing for Global Procurement Success

-

7 Key Reasons Thermal Conductivity Testing is Essential for Modern Manufacturing Success

-

How to Choose the Right Equipment for Thermal Conductivity Testing

-

5 Compelling Reasons Why Heat Flow Meters Are Essential for Energy Efficiency in Industries

-

How to Effectively Measure Thermal Conductivity with Advanced Meters

-

Understanding Thermal Conductivity Testing for Enhanced Material Performance