What is the Best Temp Sensor for Your Needs?

Choosing the right temp sensor is crucial for various applications. In industries like pharmaceuticals, food processing, and HVAC, precision matters. According to a recent report by MarketsandMarkets, the global temperature sensor market is projected to reach $4.3 billion by 2025, growing at a CAGR of 5.8%. This highlights the increasing importance of accurate temperature measurement.

Users must consider their specific needs. Not all temp sensors are the same. For instance, thermocouples are suitable for extreme temperatures, while thermistors excel in precision at lower ranges. This diversity can overwhelm newcomers. It is important to ask: Are you prioritizing accuracy, range, or response time?

Selecting a temp sensor is not merely a technical decision. It can impact overall system efficiency and reliability. Many overlook factors like installation and compatibility. Data from a Strategic Analytics report shows that up to 30% of sensor failures stem from installation errors. Thus, understanding the full scope of your requirements is key to making a wise investment.

What Are Temperature Sensors and Their Common Applications?

Temperature sensors are devices that measure heat levels. They play a critical role in various industries. From manufacturing to HVAC systems, their applications are widespread. These sensors monitor conditions and ensure optimum performance. In homes, they regulate heating and cooling systems. In healthcare, they keep track of body temperatures. The versatility of these sensors makes them essential tools.

When selecting a temperature sensor, consider the environment. Some sensors perform well in extreme conditions. Others may struggle in high humidity. Think about the specific needs of your project. Accuracy is key. A slight error can lead to larger issues. Also, consider how easy it is to install. A simple setup saves time and frustration.

Tips: Always verify the sensor's specifications. Look for features that align with your requirements. Don’t overlook the power supply needed. Sometimes, the simplest choice is the best option. Acknowledge that not all sensors are created equal. Research and find what works best for you. Make sure to test the sensor in real conditions before fully relying on it. This step can save plenty of headaches later on.

Types of Temperature Sensors: A Comprehensive Overview

When selecting a temperature sensor, various types exist to meet different needs.

Thermocouples offer a wide temperature range and fast response times.

They are great for industrial applications. However, they can be less accurate than other types if not calibrated

correctly.

RTDs, or Resistance Temperature Detectors, provide

higher accuracy. They are stable over time but tend to be more expensive. In some cases, you might find issues

with installation. Thermistors are another option, commonly used in medical

devices. They react quickly but have a limited range.

Infrared sensors offer non-contact measurement, ideal for moving objects.

Yet, they can be influenced by ambient temperature. Each type has unique features and potential drawbacks.

Understanding these can aid in making the best choice for your application.

Key Factors to Consider When Choosing a Temperature Sensor

When selecting a temperature sensor, several key factors can guide your decision. Accuracy is paramount. A study showed that temperature sensors with an accuracy within ±0.5°C are widely preferred in industrial applications. This level of precision ensures reliable readings in critical processes, such as food production or pharmaceuticals. It’s essential to assess your specific needs carefully.

Response time is another factor. Certain applications require rapid temperature changes to be detected promptly. For example, sensors meant for HVAC systems should ideally respond within seconds. The better the response time, the more efficient your system can be. However, sometimes lower-cost sensors might lag, leading to potential delays in detection. These delays can cause issues in tightly regulated environments.

Environmental conditions also play a crucial role. Different sensors perform well under various conditions, such as extreme temperatures or humidity. For outdoor applications, moisture resistance might be necessary, while some indoor setups may not require it. Often, users overlook these environmental factors, leading to suboptimal choices. Regular evaluations and adjustments to your setup can prevent future issues and ensure ongoing reliability.

Comparative Analysis of Top Temperature Sensors on the Market

When choosing a temperature sensor, various factors come into play. Certain types excel in different environments. For instance, thermocouples work well in extreme temperatures, while RTDs offer high accuracy at normal ranges. Each has its strengths and weaknesses that need consideration.

**Tips:** Think about your specific needs. Is precision crucial? Or is a broad temperature range more important? This can guide your selection process.

One downside to sensors is calibration. Many require regular recalibration to ensure accuracy. This process can be time-consuming. Consider how often you can manage this task. If not frequently, a more stable sensor type may be a better fit.

**Tips:** Research your options thoroughly. Sometimes, a less complicated sensor is what you really need. Look for simple installation processes and user-friendly features.

Temperature Sensor Comparison

This chart compares different types of temperature sensors based on their temperature ranges. Each sensor type is designed for specific applications, making them suitable for various environments.

Best Practices for Installing and Maintaining Temperature Sensors

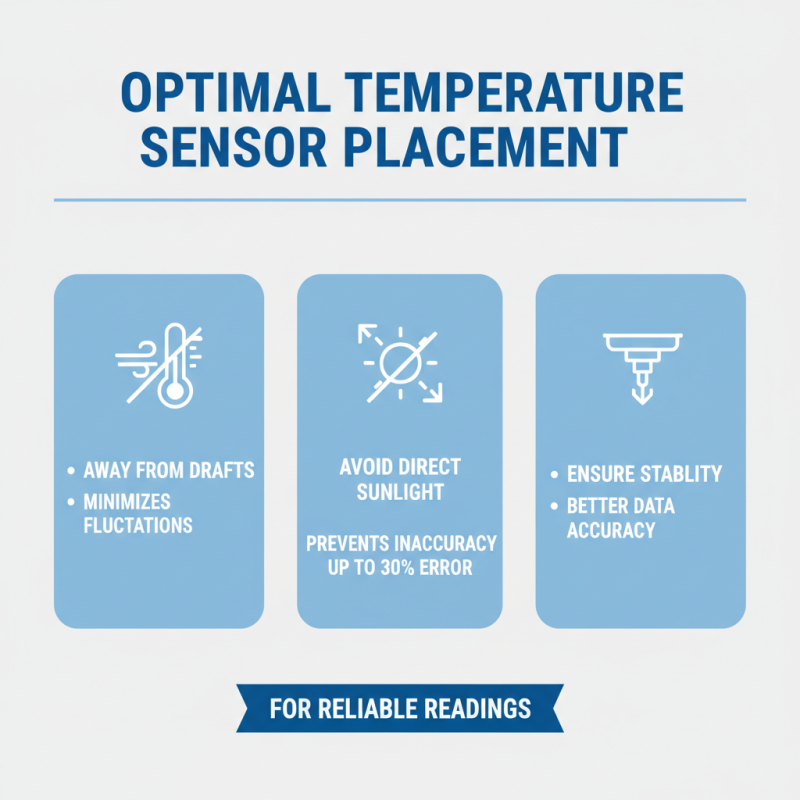

When installing temperature sensors, proper placement is critical. Place sensors away from drafts or direct sunlight. This minimizes temperature fluctuations. Studies show that incorrect placement can lead to a 30% error in readings. Keeping sensors stable ensures better data accuracy.

Regular maintenance is essential for optimal performance. Periodic calibration helps adjust readings. Industry reports indicate that sensors should be calibrated at least once a year. This ensures they remain accurate and reliable. Dust and moisture can affect sensor integrity, so check these factors regularly.

**Tips:** Ensure that the wiring is secure. Loose connections can lead to inconsistent readings. Test your sensors after installation to verify accuracy. If readings seem off, take time to troubleshoot the setup. Small adjustments can significantly enhance performance.

Related Posts

-

5 Essential Tips for Choosing the Right Temperature Sensor for Your Business Needs

-

Understanding Temp Sensors: How They Revolutionize Modern Climate Control Systems

-

Top Strategies for Enhancing Efficiency with Temperature Monitoring Sensors

-

10 Best High Temperature Sensors for Accurate Measurements in 2023

-

7 Best Thermometer Sensors for Accurate Temperature Monitoring in Various Applications

-

How to Choose the Right Temperature Sensor for Your Specific Application